Special Requirements for Waste Tire Pyrolysis Plant Design

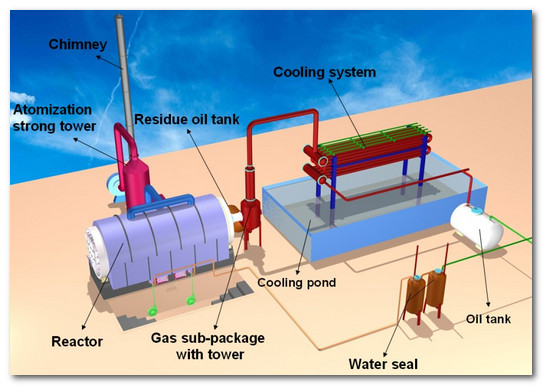

Pyrolysis plant is where cracking reaction happens. Reasonable design of pyrolysis plant is the key to the success of the entire pyrolysis process. Although the designs in many early studies could get good quality pyrolysis products, people had failed to apply these designs to industrialization. The main reason is that there are many difficulties in designing pyrolysis plant to meet the requirements. In addition to the basic requirements for pyrolysis reaction, people should also pay attention to the following issues when designing waste tire pyrolysis plant.

Pyrolysis plant is where cracking reaction happens. Reasonable design of pyrolysis plant is the key to the success of the entire pyrolysis process. Although the designs in many early studies could get good quality pyrolysis products, people had failed to apply these designs to industrialization. The main reason is that there are many difficulties in designing pyrolysis plant to meet the requirements. In addition to the basic requirements for pyrolysis reaction, people should also pay attention to the following issues when designing waste tire pyrolysis plant. The complexity of raw materials

The complexity of raw materials

There are many types of waste tires, with the development of rubber industry, the performance of tires is constantly improved. The components of waste tires are also changing and become complicated. Therefore, the raw materials to be fed into the pyrolysis reactor are uncertain. Accordingly, the technological parameter of pyrolysis plant should be flexible to adjust in a certain range.

Sealing requirements

Since the pyrolysis gas is rich in hydrogen and other flammable hydrocarbon gas, so leakage problem should be paid great attention when designing pyrolysis plant. Strict sealing should be designed to avoid leakage problem.

Requirements for high temperature

During pyrolysis reaction, the highest temperature inside the reactor can reach up to 750℃, so when considering sealed furnace design and structure design, the thermal expansion amount of the inside furnace structure is the key factor to be considered.

Insulation requirements

If the insulation of cracking tower is improper, pyrolysis gas will easily condensed at low temperature part of the cracking tower. What’s more, the condensed liquid will flow into the carbon black product in bottom part of cracking tower, which not only affect the quality of carbon black product, but also may form a sticky paste chunks that will block the carbon black outlet. Therefore, a good waste tire pyrolysis plant should have strict insulation design.

If you want to buy a pyrolysis plant equipment for your business, make sure considering the above requirements. Beston is a manufacturer of pyrolysis equipment in China, which can not only supply the quality pyrolysis machines, but also custom a reasonable pyrolysis plant design according to clients' situations with their years industry experience. You can check the detail info at www.bst-pyrolysis.com.